Packaging Waste Regulations

Are you affected?

The Packaging Waste Regulations as we know them, that have been in force since 1997, have ceased to be relevant. With effect from 1 January 2025, the new EPR regulations take effect although for 2024 compliance year, producers must still ensure they have met targets and for 2025, reprocessors and exporters continue to be bound by their 2007 regs compliance requirements.

For the old system, a business was obligated if:

1. In your last set of accounts, did your company total turnover – including any subsidiaries if you are a group – exceed £2m.

AND

2. Did your company – or group of companies that you own or are part of – handle more than 50 tonnes of packaging in the last calendar year.

‘Handle’ is packaging placed on the UK market that is owned by a business and includes the manufacture or conversion of packaging materials or packaging materials used by that business around products it supplies. It includes imports but excludes exports.

The definition of ‘Packaging’ is anything made of any materials for the containment, protection, handling, delivery and presentation of goods from the producer to the user or consumer.

If you answer ‘yes’ to 1 AND 2 above, you are obligated. If you answer ‘no’ to either, you are not obligated and can relax.

Companies that fail to register can be prosecuted although more recently, they all tend to be dealt with under the Civil Sanctions system. A list of Enforcement Undertakings accepted by the EA is available here.

If you are uncertain as to whether you are obligated, 360 Environmental can help to determine your position and if necessary get you registered.

What must you do?

If you are obligated, you must register. Up to 7th April, you have the choice of registering direct with an environmental Agency or through a scheme. After 7th April, unless an obligated business suddenly become obligated – for instance, through acquisition – it will have committed an offence and be open to prosecution by the appropriate Agency. However, it may still register with an approved Compliance Scheme and so far, nobody had had enforcement action applied for registering late.

Summary

The GB Producer Responsibility Obligations (Packaging Waste) Regulations first started in 1997 to transpose the requirements of the EU Packaging Waste Directive.

The original Regulations have been superceded and there have been additional amendments:

- Producer Responsibility Obligations (Packaging Waste) Regulations 2007

- 2010 amendments – technical changes

- 2012 amendments – applies split target to glass

- 2014 amendments – applies revised glass target

- 2016 amendments – apply the revised glass and plastic targets retrospectively to 2016 and to 2017- 2020.

- 2017 amendments – apply the revised targets for other materials 2018 – 2020

- 2020 amendments – apply the 2021 targets including the removal of the overall recovery target and the revised method of calculating the overall recycling target

Northern Ireland has its own Regulations which are pretty much identical other than their fees which are higher.

There are now approximately 6,900 companies (a total of 10,000 businesses including subsidiaries) registered through the Environment Agency (for England and Wales), the Scottish Environmental Protection Agency (for Scotland) and the Northern Ireland Environment Agency (for Northern Ireland). Nearly 6,300 of these are registered through Compliance Schemes with the remainder registered direct with the Agencies.

There have been many prosecutions by the Agencies of companies that have not registered with the largest fine being over £270k although the use of Civil Sanctions is much more common now. The Agencies have a duty to track down free-riders as well as monitor registered producers to make sure they are submitting data that is ‘as accurate as reasonably possible’.

The following illustrates the type of business that may therefore be a producer – assuming they meet the turnover threshold test.

- A chain of off-licenses supplied by UK wholesalers are likely to sell products to consumers in more that 50 tonnes of glass, plastic and metal containers. They will therefore be obligated.

- A trading company that imports products to sell to retailers might handle more than 50 tonnes in a year, taking account of the primary, secondary and tertiary packaging including pallets.

- A food manufacturer might fill over 50 tonnes of plastic trays with cardboard outers in a year that is then supplied to wholesalers.

- A pallet manufacturer may produce over 50 tonnes of pallets in a year.

- If a business exports products, then the packaging around the products must be deducted to determine whether the 50 tonne threshold is met.

Guidance on the original regulations was issued by Defra in 2006 and is still a useful summary document. But more detailed and up to date guidance for producers and recyclers is linked at the bottom of this page.

How it works

Where a business meets the threshold tests, they are required to meet annual recycling targets related to the packaging type and weight for which they are responsible. This is done by registering, either direct with the appropriate Agency (by phoning one of the numbers below) or through a compliance scheme. When registering, they must provide data for the weight of packaging handled in the previous year by material type. Government-set targets are then applied to this to produce a set of tonnages for which the company must obtain ‘evidence’ that an equivalent weight has been recycled over the year. ‘Evidence’ is known as Packaging Recovery Notes (PRNs) and is obtained from accredited sites that reprocess material and is purchased at a price that relates to supply and demand. Packaging Export Recovery Notes (PERNs) are generated by accredited businesses that export material for recycling.

For example, business 1 above ends up with a target of 150 tonnes of glass, 5 tonnes of cans and 20 tonnes of plastic derived from the targets being applied to the weights of packaging it has sold to consumers. For glass, it would need to obtain evidence that 150 tonnes had been recycled. This ‘evidence’ would need to be purchased from a reprocessor of glass – a glass melt factory, for instance, that produces new bottles from the recycling of old bottles. The reprocessor can only sell evidence for the amount of glass it recycles. If the overall UK demand for evidence is significantly less than the amount available, the laws of supply and demand will mean the price for evidence will be low. If the market is tight, the price will rise and if it is expected that there will not be enough to meet demand, the price will shoot through the roof. For producers to comply with their obligations, they MUST have sufficient evidence to match their targets. The theory is that if there is a shortage, the high prices make it more worthwhile collecting and recycling waste and that should then produce enough for people to comply.

The Advisory Committee on Packaging published an excellent Guide to the PRN system in February 2016.

Scope and technical interpretations

Whilst in theory, packaging should be fairly easy to define, in practice, there are many areas where there will be a number of interpretations of what is obligated and who should take responsibility. For instance, where packaging is formed and filled on the same production line, there are some who will argue the supplier to the production line should take the convertor obligation and others who believe – as a strict interpretation of the Regulations would suggest – it should be the production line. The Agencies have formed a view on many of these grey areas that have now been published in an Agreed Positions and Technical Interpretations (v1.19 updated March 2021) document.

The Agencies issued a position statement on silage wrap on 9 July 2019 stating that it is not considered packaging and therefore cannot have PRNs issued when it is recycled.

Registration

The legal deadline for registration is 7th April for direct registrants and 15th April for Compliance Schemes each year. As detailed below, producers can register direct with one of the three environmental Agencies – EA for England and Wales, SEPA for Scotland and NIEA for Northern Ireland – or through an approved compliance scheme. At the last count, there were 22 separate operators who all tend to operate to slightly different models but who all have to deliver the same thing – compliance on behalf of their members. A scheme takes on the legal liabilities for its members and therefore if they fail to comply, it is the scheme that gets prosecuted not the member. Schemes must ensure that their members supply accurate data which they then also register with whichever Agency they themselves are registered with. Schemes then have to meet the aggregated targets of their members and at the end of the year, demonstrate they have purchased sufficient evidence. Changes to the Regulations for 2011 mean that a Producer is not considered a registered member of a scheme unless they have paid the Scheme’s membership fee and the Agency fee and have supplied data for registration.

From a producer point of view, there are pros and cons for each option. To register direct with an Agency, the producer has to complete a table relating to the packaging placed on the market and send it to the Agency with a fee by 7th April. The Agencies have comprehensive guidance (WMP1) on registration. To register with a scheme, a producer must supply similar data to the scheme although the scheme will generally help to translate data into the necessary table format. The scheme will then register the member by 7th April. However, most schemes have a cut off data for data and fee payment of around the end of February to enable them to check and put together the aggregated data for the Agency.

Whether registering direct or submitting data to a Scheme, every producer and Compliance Scheme must electronically sign off submitted data and the Certificate of Compliance through an ‘authorised signatory’ using their set up login.

For 2016 onwards, Authorised Signatories can delegate responsibility by submitting a form to the Agency.

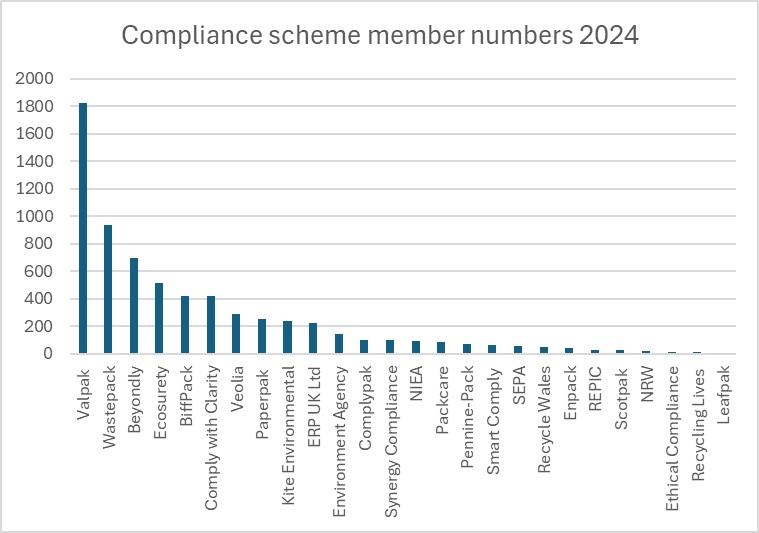

The graph below shows the number of registrations in 2022 as at 17/05/2022. A full list can be seen in the Data section.

How can you register directly with the Agency?

The Regulations allow producers to register directly. This means that they retain full legal liability – unlike joining a scheme where that liability passes to the scheme. To register, they must:

- Complete the registration process by 7th April

- Pay a registration fee to the Agency that MUST be with the Agency before 7th April

- If their obligation is greater 500 tonnes, complete an Operational Plan

- During the compliance period, purchase the necessary evidence to meet their targets

- Submit a Certificate of Compliance to the Agency by 31 January in the year following a compliance period

Direct registration is carried out through the National Packaging Waste Database (NPWD). To start the registration process, a producer must contact the Agency relative to their location (EA for England and Wales, Sepa for Scotland and the NIEA for Northern Ireland) to get a login. WITHOUT THIS, YOU CANNOT REGISTER DIRECT.

Their contact details are as follows:

- In England and Wales: 08708 506 506 or email

- In Scotland: 01786 457700 or email

- In Northern Ireland: 028 9056 9338

They will need the following details to issue a login:

- Name

- Position within company

- Telephone Number

- Fax number

- E-mail address

- Company address

- Companies House registration no (if applicable)

Once you have the login, you can go to the NPWD site, login and download or complete the forms.

The Agencies have issued a comprehensive Guidance document for registration.

Data requirements

The data that has to be provided relates to the supply chain and is divided into 4 activities:

- The Raw Material Manufacturer that produces the material that packaging is made from eg a paper mill producing corrugated cardboard.

- The Convertor that turns the material into packaging eg a cardboard box manufacturer

- The Pack-filler that places products into packaging eg a food manufacturer

- The Seller who passes the packaged product onto the end user who then discards that packaging eg a supermarket

These four activities share 100% of the responsibility for the packaging. The Raw Material Manufacturer takes 6%, the convertor takes 9%, the packfiller takes 37% and the seller takes 48%. Basically, therefore, each bit of packaging that ends up in the UK dustbin will have had 100% responsibility applied through the supply chain.

So if a manufacturer of baked beans (with a turnover above £2m in the previous financial year) fills 100 tonnes of steel cans, they would be obligated under these regulations (as it has handled more than 50 tonnes of packaging that has gone onto the market). But when it reports its data, it will only have targets applied to 37 tonnes of that because they are a packfiller and pass the cans onto someone else who sells them to the final consumer.

Business targets for recycling and recovery are set for each year by Defra to ensure that the UK continues to meet the 2008 EU targets and is on the right trajectory to meet future target expectations.

The Regulations apply to nearly all packaging although there are some exceptions. For instance, there has to be ‘supply’ where the packaging is passed from one part of the chain to the next. If it is used only for internal use eg as transit packaging between warehouses belonging to the same company, then that company does not have to report it.

For imported products, the company taking ownership when it comes through customs is considered the producer and must take the rolled up obligation for the activities that happened prior to import into the UK. For exported products, the packaging must be reported but it does not have the targets applied.

Different recycling targets are applied to different materials and producers must therefore report under 7 material types:

- Paper/card eg cartons, labels of certain types, layerboard, paper bags

- Glass eg bottles, jars

- Aluminium eg cans, aerosols, foil trays

- Steel eg cans, drums

- Plastic eg bottles, pallet wrap, bags

- Wood eg pallets, dunnage

- ‘Other’ which includes things like jute and cork.

The recycling and recovery targets applied to the activity percentage (packfiller, seller etc) applied to the tonnage of packaging placed on the market by a company determines what a company’s tonnage obligation is.

360 have produced an Obligation Calculator which can be found on our Wastesupport website.

If a producer’s turnover is between £2m and £5m, they have the option of registering as a ‘small producer’ under the ‘allocation’ system.. A new Regulatory Position Statement has been introduced (Sept 2022) requiring businesses wishing to use this to contact the EA beforehand. This entitles them to calculate data more simply than full producers through a government set tonnage multiplied by their turnover in millions of pounds. For 2022/23, the figure is set at 35 tonnes per million pounds of turnover. Therefore, a company that had a turnover of £3.458m in their last accounts would have an obligation of 121.03 tonnes rounded up to 122 tonnes. This would be in the predominant packaging material handled by the company. Whilst this clearly offers administrative benefits, it is nevertheless an option that companies only tend to use if it gives them a lower obligation than they would get using the full producer method of calculation.

Targets

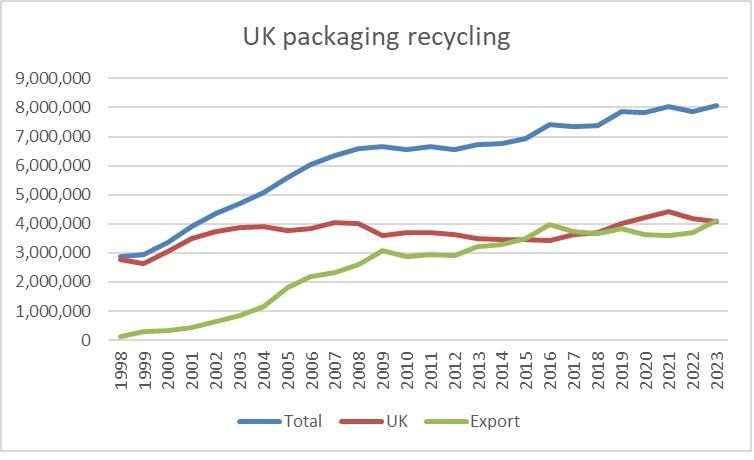

Defra normally try and set targets at least three years in advance. Each time it wishes to change or add to the targets, it must go through a consultation process that can take up to 6 months. Since the Regulations started, the amount of packaging being recycled has more than doubles although the majority of that growth has come from exports. The Recovery line includes packaging that has been recovered through Waste to Energy.

The graph below shows the level of recycling achieved from the start of the Regulations.

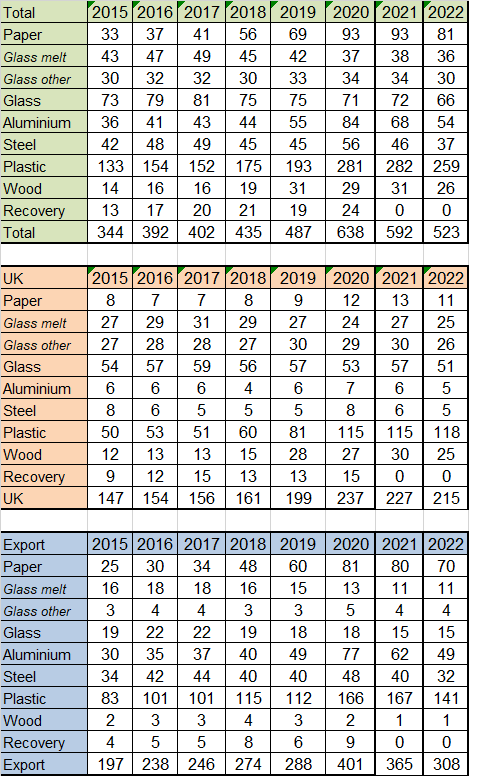

The targets have now been set fthrough to 2023. Beyond that, the targets are part of the EPR consultation process. These are the targets applied to the obligated tonnage for each business. A compliance scheme will therefore have to procure PRNs/PERNs for the sum total of all its members obligations.

Each material has its own individual recycling target. In addition, an overall recycling target will be set that will generally be larger than the sum of the material recycling targets. The difference can be made up with evidence from any material – normally the cheapest. There is also an even higher overall recovery target and the difference between this and the overall recycling target can be made up with evidence from either material recycling or recovery. Recovery evidence is generally where waste containing an element of packaging goes through an energy recovery process eg incineration with energy recovery.

The 2022/23 targets are shown below. The glass target has been split since 2013 and as a minimum, the melt target must now be met with PRNs from melt activities. The remaining target can be met by PRNs from either melt of aggregates activity. The glass target was reduced in March 2014 to take account of revised ‘placed on the market’ data. In 2016, the plastic target was reduced to take account of revised ‘placed on the market data’.

Business targets:

The targets for 2024 are as follows:

- Paper – 83%

- Glass – 82%

- Aluminium – 69%

- Steel – 87%

- Plastic – 61%

- Wood – 42%

- Overall recycling – 80%

72% of the glass target must be met by melt applications.

For those using the allocation system, they must multiply their turnover in the latest accounts by 35 tonnes and obtain PRNs for that amount in the predominant material.

Fees

Regardless of whether a producer registers direct or through a scheme, they have to pay a fee that goes to the Agency.

| Full producer | Small producer | Subsidiaries | |

| Direct registrant | £776 | £562 | £180 ea for first four £90 ea for 5-20 £45 ea for any others Subsidiaries in a Group Registration that use the Small Producer option do not pay subsidiary fees. |

| Through a Scheme | £564 | £345 |

The Agencies also charge a £110 fee for late registrations and £220 for re-submissions where producers have to recalculate data because of errors.

Schemes charge a variety of fees in addition to the Agency fee. Some charge a low membership fee of £300-500 but then add on costs through additional services – visits etc – and a margin on the PRNs whilst others charge a high fee that covers everything in relation to scheme membership.

Producers also have to remember that regardless of which route they take, they must pay for the cost of PRNs needed to satisfy their obligation. There is little transparency on these costs and it is difficult for a producer to compare between schemes, let alone know whether they are paying a competitive price if they are a direct registrant. Indicators like t2e and letsrecycle give a picture of sorts, but they do not necessarily paint a true picture as they will be dictated by varying circumstances. But 360 Environmental can help Producers to decide which route to take and to provide independent advice on which scheme might best suit them.

Reprocessors and exporters

Evidence can only be issued by approved UK reprocessors or exporters in the form of PRNs and PERNs.

From 1 Jan 2021, new Basel Convention rules apply to the export of plastic waste including packaging. The EA has produced a comprehensive guidance document that explains the changes.

Interim sites

Where an exporter wishes to send packaging waste to an interim site prior to that packaging waste going on to an approved Part C they need to ensure that they abide by the expectations of the Environment Agency (it is assumed that the other Agencies would apply the same rules). These are laid out in EA interim site response from guidance received from the EA on 18/01/24.

NPPP

The EA allows waste plastic processed into flakes under the Non-Packaging Plastics Protocol (NPPP) to be classed as non-waste and for the process to therefore be PRNable. Detailed guidance on this was published by the EA in 2021 that emphasised the need for those wishing to export NPPP flakes as non-waste to obtain evidence from the competent authority in the receiving country that they accepted that this material was regarded as non-waste.

Accreditation

For each compliance year, reprocessors and exporters have to submit applications for approval by September 30th in the previous year. The latest Guidance document (this supercedes GN01v7) includes information on the registration of facilities operating under the End of Waste Regulations. The EA has also (4 Sep 2014) issued an Accreditation Table which lists the recycling processes that are eligible to issue PRNs against.

Exporters to non-OECD countries must provide Broadley Equivalent documentation to demonstrate that the overseas site operates broadley to EU standards. This lists the countries and the Broadly Equivalent documentation requirements. (August 2020).

Reprocessors and exporters have to provide quarterly returns showing the amount of material they have received and the amount of PRNs they have issued. This data is published on NPWD normally on the 22nd of the month following a quarter except for Q4 which is not published until the end of March.

There are two types of approval. For those issuing less than 400 tonnes of evidence a year, they must pay a fee of £505. For those issuing more than 400 tonnes, they must pay £2,616 for approval. Reprocessors and exporters no longer have to submit an annual independent audit of their processes.

The table below shows the number of UK and Export accreditations as of 17/05/22..

Compliance Monitoring Plans

Under the regulations, the various Agencies are required to publish their Compliance Monitoring Plans before the start of the compliance year.

What next?

Defra has published its consultation response on a revised Producer Responsibility system for packaging to start in 2024. The PRN will be retained but is currently the subject of a consultation (closing date 21st May 2022).

Targets for 2023 will remain the same as for 2022..

There is an Advisory Committee on Packaging that works with Defra on future changes. More details can be found here.

Useful links with further information

GOV.UK – Producer Guidance

GOV.UK – Reprocessor/exporter guidance

Packaging protocols for the issue of PRNs

Producer Responsibility: Examples of broadly equivalent standards for packaging and equivalent standards for WEEE and batteries (v6 August 2019)

Broadly equivalent standards updated Sep 2021 (html)

Technical Interpretations document

Other countries

Germany – summary of their packaging ordinance

Producer Responsibility

- Overview

- WEEE Regulations

-

- Data

- Used EEE exports

- Packaging Waste Regulations

-

- Packaging Obligation Calculator

-

- PRN Prices

-

- Data

-

- Agency Communications

- Extended Producer Responsibility (EPR)

- Essential Requirements

- Batteries Regulations

- End of Life Vehicle Regulations

- Agency Comms

- Plastic Packaging Tax

- Deposit Return Scheme (DRS)